Revolutionizing Warehouse Automation: The Rise Of Robotic Palletizers

In the fast-paced world of warehousing, robotic palletizers are revolutionizing the way goods are handled and shipped. From increased efficiency to improved safety measures, these advanced machines are changing the game for businesses both big and small. Join us as we explore the rise of robotic palletizers and uncover how they are transforming warehouse automation as we know it. Prepare to be amazed by the innovation and ingenuity behind this cutting-edge technology.

- The Evolution of Warehouse Automation Technology

Warehouse automation technology has come a long way in recent years, with robotic palletizers leading the charge in revolutionizing the way goods are stored and distributed. These advanced machines are at the forefront of the evolution of warehouse automation technology, representing a significant shift in how warehouses operate and streamline their processes.

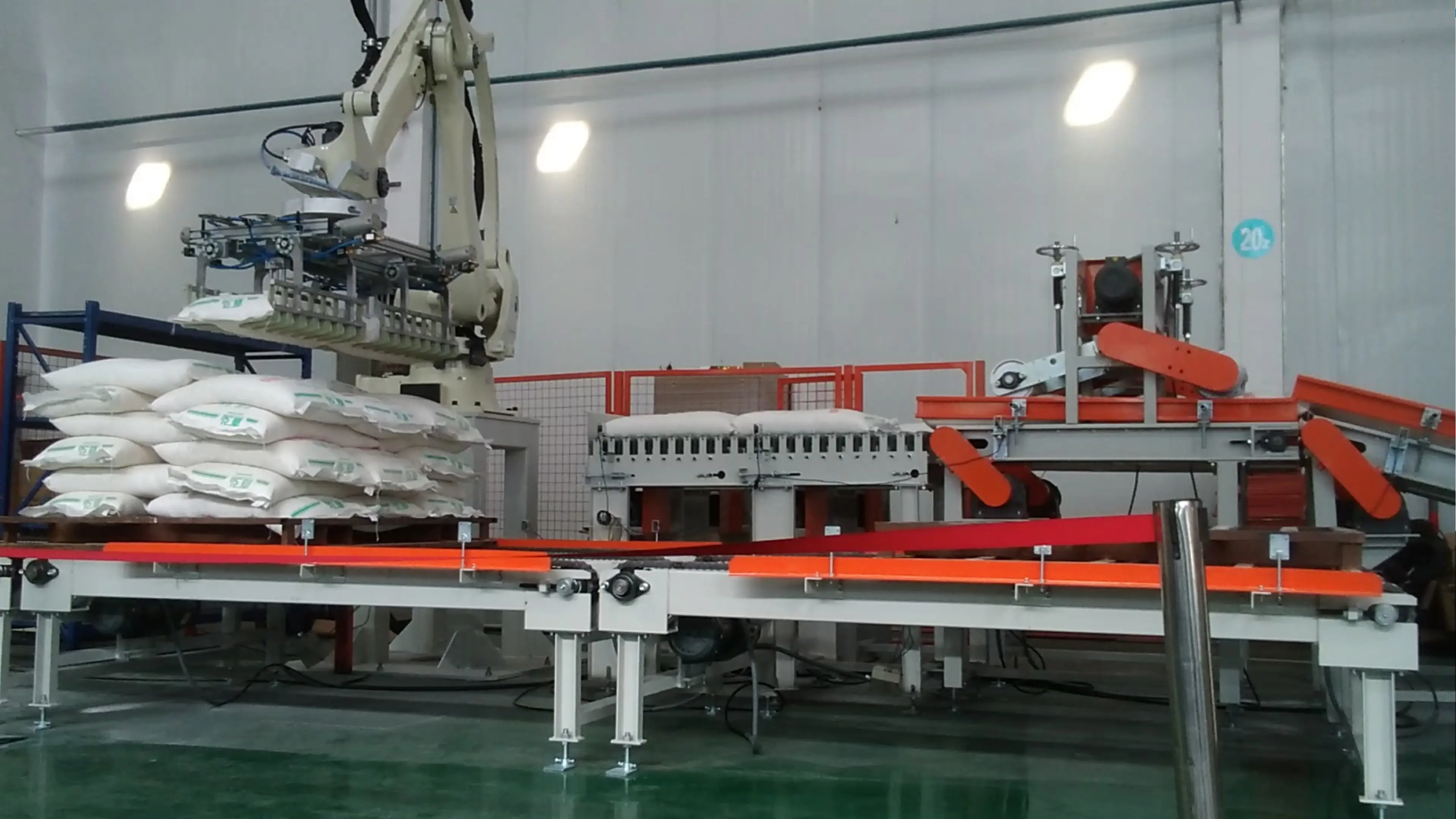

Robotic palletizers are automated machines designed to stack goods on pallets with precision and efficiency. They have become increasingly popular in warehouses of all sizes due to their ability to handle heavy loads, work in confined spaces, and operate around the clock without the need for breaks. This technology has transformed the way warehouses operate, allowing for faster throughput, reduced labor costs, and improved safety for workers.

One of the key features of robotic palletizers is their adaptability and flexibility. These machines can be easily programmed to handle a wide range of products, from boxes to bags to crates, and can adjust their stacking patterns to accommodate different pallet sizes and configurations. This flexibility allows warehouses to optimize their storage space and maximize efficiency, ultimately improving their bottom line.

In addition to their versatility, robotic palletizers also offer increased precision and accuracy in stacking and positioning goods on pallets. This level of automation ensures that products are handled with care and consistency, reducing the risk of damage during the storage and transportation process. This not only improves the overall quality of the goods being stored but also enhances the customer experience by ensuring that orders are fulfilled accurately and on time.

Furthermore, robotic palletizers are equipped with advanced sensors and software that enable them to work collaboratively with other machines and systems in the warehouse. This interconnectedness allows for real-time monitoring and data sharing, enabling warehouses to track inventory levels, predict demand, and optimize workflows. By leveraging this technology, warehouses can operate more efficiently, reduce waste, and meet the demands of a rapidly changing market.

As warehouse automation technology continues to evolve, the role of robotic palletizers is only expected to grow. These machines are at the forefront of a new era of warehouse optimization, where flexibility, precision, and efficiency are paramount. By embracing this technology, warehouses can stay ahead of the competition, adapt to shifting consumer preferences, and drive innovation in the industry.

In conclusion, robotic palletizers are revolutionizing warehouse automation by reshaping the way goods are stored, stacked, and distributed. These advanced machines are leading the charge in the evolution of warehouse technology, setting new standards for efficiency, precision, and adaptability. As warehouses continue to embrace automation, robotic palletizers will play a crucial role in driving growth, streamlining operations, and ensuring a competitive edge in the market.

- The Role of Robotic Palletizers in Modern Warehouses

As technology continues to advance, modern warehouses are embracing the use of robotic palletizers to streamline their operations and improve efficiency. These innovative machines have revolutionized warehouse automation and have become an integral part of the supply chain process.

Robotic palletizers are automated systems that are designed to stack and organize products onto pallets with precision and speed. These machines have the capability to handle a wide range of products, from boxes and bags to crates and barrels. By utilizing sensors and advanced algorithms, robotic palletizers can analyze the size, weight, and shape of each item to create the most efficient pallet configuration.

One of the key advantages of robotic palletizers is their ability to increase productivity and reduce labor costs. These machines can work around the clock without breaks or fatigue, ensuring a constant flow of palletized goods. This allows warehouses to maximize their output and meet increasing customer demands. Additionally, robotic palletizers require minimal human intervention, freeing up workers to focus on more complex tasks that require human judgment and decision-making.

Another benefit of robotic palletizers is their ability to improve safety in the warehouse environment. By automating the palletizing process, the risk of injuries due to heavy lifting or repetitive motions is greatly reduced. This can lead to lower insurance costs and fewer workplace accidents, creating a safer and more efficient work environment for employees.

In addition to increasing efficiency and reducing costs, robotic palletizers also offer greater flexibility and adaptability in warehouse operations. These machines can easily be reprogrammed to handle different types of products or accommodate changes in production needs. With the ability to adjust pallet configurations on-the-fly, warehouses can quickly respond to fluctuating demand and optimize their storage space.

The integration of robotic palletizers into modern warehouses is transforming the way goods are handled and distributed. These machines not only streamline the palletizing process but also contribute to overall operational excellence. With their accuracy, speed, and versatility, robotic palletizers are revolutionizing warehouse automation and setting new standards for efficiency in the supply chain industry.

In conclusion, the role of robotic palletizers in modern warehouses cannot be overstated. These innovative machines are driving the evolution of warehouse automation and reshaping the way goods are palletized and distributed. By leveraging the power of technology, warehouses can achieve higher levels of productivity, safety, and flexibility, ultimately improving their competitiveness in today's fast-paced market.

- Benefits of Implementing Robotic Palletizers in Warehousing Operations

In recent years, there has been a significant shift in the way warehouses operate, with an increasing number of companies turning to robotic palletizers as a solution to streamline their operations. These advanced machines have revolutionized the way goods are handled and stored, offering numerous benefits that have transformed the warehouse automation industry.

One of the key advantages of implementing robotic palletizers in warehousing operations is the significant increase in efficiency. These machines are able to work non-stop, 24/7, without the need for breaks or rest, unlike human workers. This results in a much faster and more consistent palletizing process, reducing the overall time taken to complete tasks and increasing productivity. With robotic palletizers, warehouses are able to handle larger quantities of goods in a shorter period, allowing for quicker turnaround times and improved customer satisfaction.

Additionally, the use of robotic palletizers in warehouses has been shown to enhance workplace safety. By taking over the manual labor of palletizing, these machines help reduce the risk of injuries and accidents that are commonly associated with manual handling tasks. This not only ensures the well-being of employees but also minimizes the potential for costly workers' compensation claims and downtime due to injuries.

Moreover, robotic palletizers offer a higher degree of accuracy and precision compared to manual labor. These machines are equipped with advanced technology that enables them to accurately stack and arrange products on pallets according to predefined specifications. This level of consistency ensures that goods are handled with care and are less likely to be damaged during the palletizing process, ultimately reducing wastage and improving overall product quality.

Another benefit of implementing robotic palletizers in warehousing operations is the significant cost savings that they can bring. While the initial investment in these machines may be substantial, the long-term savings in terms of labor costs, increased productivity, reduced errors, and improved efficiency far outweigh the upfront expenses. In the long run, warehouses that utilize robotic palletizers are able to operate more competitively and profitably in a fast-paced market environment.

Overall, the rise of robotic palletizers in warehouse automation represents a significant step forward in the evolution of the industry. By harnessing the power of advanced technology, companies are able to reap a wide range of benefits, from increased efficiency and workplace safety to improved accuracy and cost savings. As the demand for faster, more reliable, and cost-effective warehousing solutions continues to grow, robotic palletizers are sure to play a crucial role in shaping the future of warehouse automation.

- Challenges and Considerations for Adopting Robotic Palletizers

Over the past few years, the warehouse automation industry has witnessed a significant transformation with the rise of robotic palletizers. These advanced machines have revolutionized the way warehouses handle and stack pallets, streamlining the entire process and improving efficiency. However, with every new technology comes challenges and considerations that must be carefully examined before adoption.

One of the key challenges of incorporating robotic palletizers into a warehouse setting is the initial cost. While these machines offer numerous benefits in terms of productivity and accuracy, they require a significant investment upfront. This can be a deterrent for some warehouse operators who may be hesitant to commit to such a large expenditure. In addition to the cost of the robot itself, there are also expenses associated with installation, training, and maintenance that must be taken into account.

Another consideration when adopting robotic palletizers is the space required for their operation. These machines can be quite large and may need to be accommodated in a specific area within the warehouse. This can pose a challenge for facilities that are already operating at maximum capacity and may struggle to find the necessary space for a new piece of equipment. Proper planning and layout adjustments may be necessary to ensure that the robot can operate efficiently without disrupting other operations.

Furthermore, training staff to operate and maintain robotic palletizers is essential for successful implementation. These machines are complex and require skilled individuals to operate them effectively. Providing training to existing employees or hiring specialized technicians can be an additional cost and may require a significant time investment. Ensuring that employees are properly trained and comfortable with the technology is crucial to maximizing the benefits of robotic palletizers.

Integration with existing warehouse management systems is another consideration when adopting robotic palletizers. These machines must be able to communicate seamlessly with other technology within the warehouse to ensure a smooth and efficient workflow. Compatibility issues may arise if the robot is not properly integrated with existing systems, leading to disruptions in operations and decreased productivity. A thorough evaluation of the compatibility of the robot with current technology is necessary before implementation.

Despite these challenges and considerations, the benefits of adopting robotic palletizers in a warehouse setting cannot be overlooked. These machines offer increased efficiency, accuracy, and productivity, ultimately leading to cost savings and improved customer satisfaction. By carefully assessing the potential challenges and considerations associated with robotic palletizers and developing a comprehensive implementation plan, warehouse operators can successfully revolutionize their automation processes and stay ahead of the competition in an increasingly competitive market.

- The Future of Warehouse Automation: Opportunities and Innovations.

The advancements in technology have revolutionized the way warehouses operate, leading to increased efficiency and productivity. One such innovation that has gained widespread popularity in recent years is robotic palletizers. These automated machines have transformed the warehouse industry, offering a range of opportunities and innovations that have reshaped the future of warehouse automation.

Opportunities for Efficiency:

Robotic palletizers have paved the way for improved efficiency in warehouse operations. These machines are capable of handling heavy loads and palletizing products at a faster rate than human workers. This not only increases productivity but also reduces the risk of injuries associated with manual labor. With robotic palletizers, companies can streamline their operations and maximize their output without compromising on quality.

Innovations in Technology:

The rise of robotic palletizers has been fueled by advancements in technology. These machines are equipped with sophisticated sensors and software that allow them to accurately position and stack products with precision. Some models even have the ability to adapt to different packaging sizes and shapes, making them versatile for a wide range of products. Additionally, robotic palletizers can be integrated with other automation systems, such as conveyor belts and robotic arms, to create a seamless workflow in the warehouse.

Cost-Effectiveness:

While the initial investment in robotic palletizers may be significant, companies can expect long-term cost savings and a high return on investment. These machines require minimal maintenance and have a longer lifespan compared to manual labor, reducing overall operational costs. In addition, robotic palletizers can operate continuously without breaks, leading to increased production uptime and decreased labor costs. As a result, companies can achieve higher levels of efficiency while reducing operational expenses, making robotic palletizers a cost-effective solution for warehouse automation.

Improved Safety:

Safety is a top priority in warehouse operations, and robotic palletizers have significantly enhanced workplace safety. By automating the palletizing process, companies can minimize the risk of accidents and injuries associated with manual handling of heavy loads. Robotic palletizers are designed to operate in a closed environment, away from workers, further reducing the likelihood of workplace accidents. With improved safety measures in place, companies can create a safer work environment for their employees while maintaining high levels of productivity.

The rise of robotic palletizers signifies a new era in warehouse automation, offering a range of opportunities and innovations that have transformed the industry. These machines have revolutionized the way products are handled and palletized, leading to increased efficiency, cost-effectiveness, and safety in warehouse operations. As technology continues to evolve, robotic palletizers will continue to play a crucial role in shaping the future of warehouse automation, driving growth and innovation in the industry.

Conclusion

In conclusion, the rise of robotic palletizers is revolutionizing warehouse automation by streamlining operations, increasing efficiency, and improving safety standards. These cutting-edge technologies are reshaping the way businesses approach logistics and are paving the way for a more advanced and efficient supply chain process. As companies continue to adopt robotic palletizers, the future of warehouse automation looks brighter than ever. With continued advancements in technology and the increasing demand for efficiency, it's clear that robotic palletizers are here to stay and will continue to play a significant role in the evolution of warehouse automation.

Contact: Heidi

Tel: +86 183 2103 6277

E-mail: Heidi@cian-sung.com

WhatsApp:+86 183 2103 6277

Add:

【International Marketing Department】

11A Yindong BLG. No.58 Xinjinqiao RD. Pudong Shanghai, China

【Suzhou Factory】

Anqing Village, Sunjiatang Road, Zhangjiagang City, Suzhou

【Xuzhou Factory】

No. 19 Wujiang Road, Taishang Industrial Zone, Yitang Town, Pizhou City, Jiangsu Province, China