Revolutionizing Warehousing: The Benefits Of A Robotic Palletizing System

Are you looking to streamline your warehouse operations and increase efficiency? Look no further than the revolutionary technology of robotic palletizing systems. In this article, we will explore the numerous benefits of implementing a robotic palletizing system in your warehouse, from increased productivity to improved worker safety. Join us as we delve into the future of warehousing and the immense advantages that come with embracing automation.

- Introduction to Robotic Palletizing Systems

Revolutionizing Warehousing: The Benefits of a Robotic Palletizing System- to Robotic Palletizing Systems

In today’s fast-paced world of logistics and warehousing, efficiency and productivity are key factors in the success of any operation. One way that businesses are achieving higher levels of efficiency is through the use of robotic palletizing systems. These innovative systems are revolutionizing the way goods are handled and stored in warehouses, offering a range of benefits to businesses of all sizes.

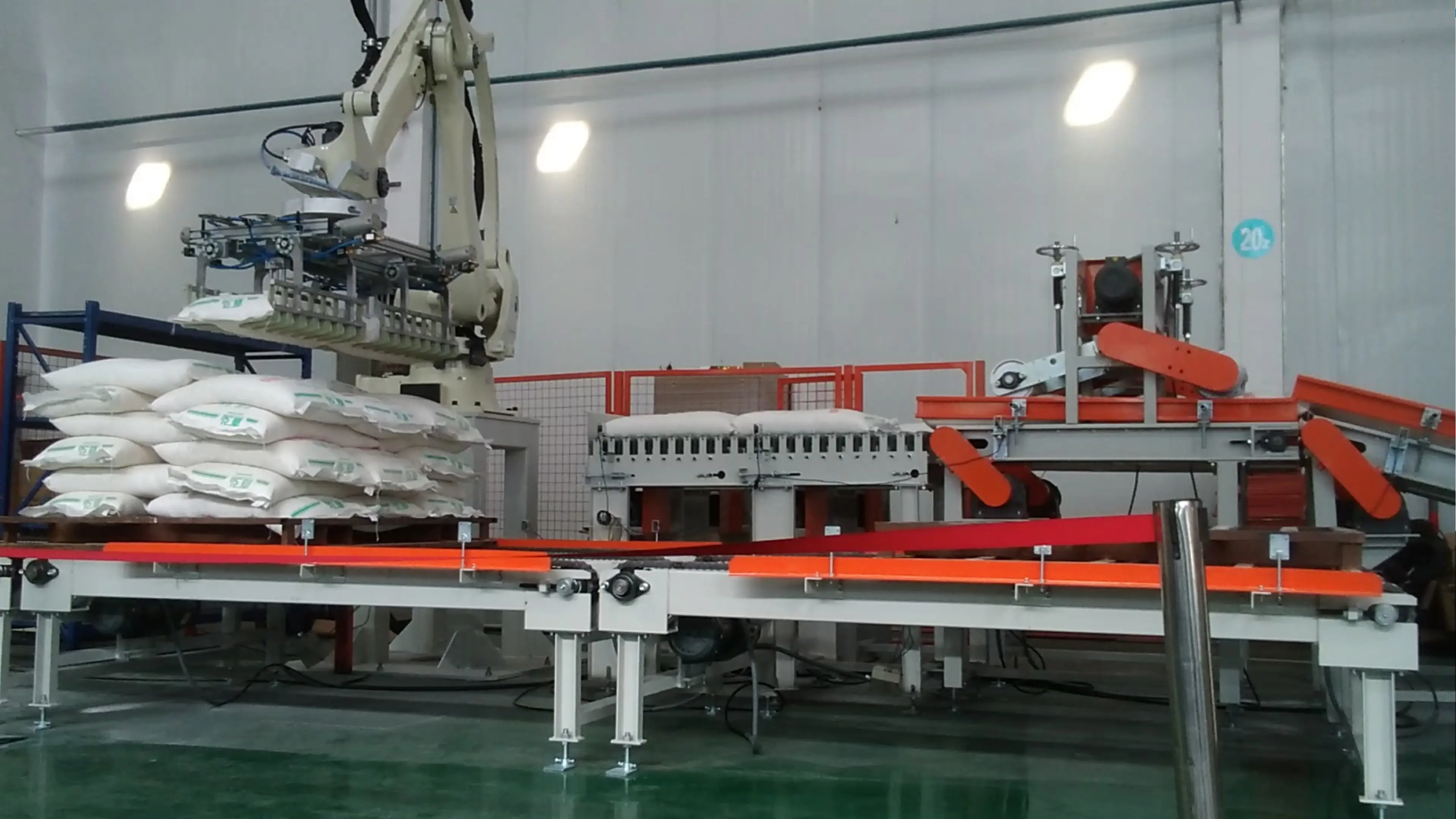

Robotic palletizing systems are automated machines that are designed to stack, store, and transport goods on pallets without the need for human intervention. These systems can handle a wide range of products, from boxes and cartons to bags and drums, making them versatile solutions for any type of warehousing operation. By utilizing robotics technology, businesses can significantly reduce the amount of manual labor required in the warehouse, leading to higher productivity and lower operational costs.

One of the key benefits of a robotic palletizing system is its ability to improve safety in the warehouse. Manual palletizing can be a labor-intensive and hazardous task, as workers may be at risk of injuries from lifting heavy objects or working in repetitive motions. By automating the palletizing process, businesses can create a safer working environment for their employees and reduce the risk of workplace injuries.

In addition to improving safety, robotic palletizing systems can also increase efficiency and accuracy in the warehouse. These systems are capable of stacking goods with precision and consistency, reducing the risk of errors and damage to products. By ensuring that pallets are stacked correctly and securely, businesses can streamline their operations and minimize the risk of damaged goods or lost inventory.

Furthermore, robotic palletizing systems can help businesses optimize their warehouse space. By stacking goods in a more organized and efficient manner, businesses can make better use of their available space and maximize their storage capacity. This can lead to a more streamlined workflow and improved inventory management, ultimately resulting in cost savings and increased profitability for the business.

Another advantage of robotic palletizing systems is their flexibility and scalability. These systems can be easily programmed to accommodate different types of products and packaging, allowing businesses to adapt to changing market demands and customer requirements. Whether handling small or large volumes of goods, robotic palletizing systems can be customized to meet the specific needs of the business, making them a versatile and cost-effective solution for warehousing operations of all sizes.

In conclusion, robotic palletizing systems are revolutionizing the way goods are handled and stored in warehouses, offering a range of benefits including improved safety, efficiency, accuracy, and space optimization. By implementing a robotic palletizing system, businesses can streamline their operations, reduce costs, and increase productivity, ultimately gaining a competitive edge in today’s dynamic marketplace.

- Efficiency and Productivity Improvements

Efficiency and Productivity Improvements

In the fast-paced world of modern logistics and warehousing, the need for efficiency and productivity improvements is more crucial than ever. With increasing demand for faster order processing and shipping times, businesses are constantly seeking ways to streamline their operations and maximize their output. One of the most innovative solutions to emerge in recent years is the robotic palletizing system.

A robotic palletizing system is a state-of-the-art technology that automates the process of stacking and organizing products on pallets. By utilizing robotic arms and advanced software algorithms, these systems can quickly and accurately palletize a wide range of products, from boxes to bags to drums. This automation allows for faster and more efficient loading and unloading of goods, reducing the time and labor required for these tasks.

The key benefit of a robotic palletizing system is its ability to significantly enhance efficiency and productivity in the warehouse. By taking over the manual labor of palletizing, these systems can drastically reduce the time it takes to process orders and prepare shipments. This means that businesses can fulfill orders more quickly, leading to faster delivery times and ultimately higher customer satisfaction.

Furthermore, robotic palletizing systems can also improve accuracy and consistency in the warehouse. By eliminating human error in the palletizing process, these systems can ensure that each pallet is stacked correctly and securely, reducing the risk of damaged products during shipping. This not only saves businesses money on replacements and returns but also enhances their reputation for reliability and quality.

Another advantage of a robotic palletizing system is its versatility and scalability. These systems can be easily customized to handle a wide range of product types and sizes, making them suitable for a variety of industries and applications. Additionally, as businesses grow and expand their operations, robotic palletizing systems can be easily expanded or reconfigured to accommodate increased demand, allowing for seamless scalability without the need for major investments in additional equipment or labor.

Overall, the adoption of a robotic palletizing system can bring a wealth of benefits to businesses looking to improve their efficiency and productivity in the warehouse. By automating the palletizing process, businesses can reduce labor costs, increase throughput, and enhance accuracy, ultimately leading to greater overall profitability and competitiveness in the market. With these advantages in mind, it is clear that robotic palletizing systems are revolutionizing the way warehouses operate and setting new standards for efficiency and productivity in the industry.

- Cost Savings and Return on Investment

In today's fast-paced and competitive business environment, companies are constantly seeking ways to improve efficiency, reduce costs, and increase profitability. One area where significant cost savings and return on investment can be realized is in the realm of warehousing. As technology continues to advance, companies are turning to robotic palletizing systems to revolutionize their warehousing operations.

A robotic palletizing system is a sophisticated automated solution that uses robots to stack and organize products on pallets. These systems are designed to handle a wide range of products, from boxes to bags to crates, with speed and precision. By implementing a robotic palletizing system, companies can greatly improve the efficiency of their warehousing operations.

One of the major benefits of a robotic palletizing system is the significant cost savings it can provide. Traditional methods of palletizing involve manual labor, which can be time-consuming, labor-intensive, and prone to errors. By using robots to palletize products, companies can eliminate the need for manual labor, reducing labor costs and improving accuracy. Robots can work continuously without breaks, increasing productivity and throughput in the warehouse.

In addition to cost savings, a robotic palletizing system can also provide a strong return on investment. While the initial investment in a robotic palletizing system may be significant, the long-term benefits far outweigh the costs. By improving efficiency and reducing labor costs, companies can realize a quick return on their investment. In fact, many companies see a return on investment in as little as one to two years after implementing a robotic palletizing system.

Another benefit of a robotic palletizing system is the flexibility it provides. These systems can be easily programmed to handle a wide variety of products and packaging configurations. This flexibility allows companies to adapt to changing market demands and production requirements quickly and easily. Additionally, robotic palletizing systems can be integrated with other warehouse automation systems, such as conveyor belts and sorters, further improving efficiency and productivity.

Not only do robotic palletizing systems improve efficiency and reduce costs, but they also improve workplace safety. Manual palletizing can be physically demanding and hazardous for workers, leading to potential injuries and accidents. By automating the palletizing process with robots, companies can create a safer work environment for their employees, reducing the risk of injuries and improving overall workplace morale.

In conclusion, a robotic palletizing system offers numerous benefits to companies looking to revolutionize their warehousing operations. From cost savings and return on investment to improved efficiency and workplace safety, the advantages of implementing a robotic palletizing system are clear. As technology continues to evolve, companies that invest in automation and robotics will be better positioned to succeed in the competitive business landscape.

- Enhanced Safety Measures

As the demand for efficient and safe warehousing operations continues to grow, companies are turning to robotic palletizing systems to revolutionize their processes. These advanced systems are designed to enhance safety measures in the warehouse, ensuring a smooth and secure operation from start to finish.

One of the primary benefits of a robotic palletizing system is its ability to reduce the risk of workplace injuries. By automating the palletizing process, these systems eliminate the need for manual labor in potentially hazardous situations. Workers no longer have to lift heavy loads or maneuver awkwardly shaped items, significantly reducing the likelihood of strains, sprains, and other physical injuries.

In addition to improving safety for employees, robotic palletizing systems also enhance warehouse security. These systems are equipped with sensors and cameras that constantly monitor the work area, detecting any potential hazards or obstructions in real-time. This proactive approach to safety helps prevent accidents before they occur, ensuring a safer work environment for everyone involved.

Furthermore, the precision and accuracy of robotic palletizing systems contribute to an overall increase in warehouse efficiency. These systems can palletize items quickly and with minimal error, reducing the risk of damaged goods and costly rework. By streamlining the palletizing process, companies can increase their productivity and throughput, ultimately leading to higher profitability and customer satisfaction.

Another key advantage of robotic palletizing systems is their versatility and adaptability. These systems can be programmed to handle a wide range of products, from boxes and bags to crates and containers. This flexibility allows companies to optimize their warehouse operations and meet the changing demands of the market without having to invest in additional equipment or personnel.

Overall, the implementation of a robotic palletizing system offers numerous benefits for companies looking to enhance safety measures in their warehouses. By reducing the risk of workplace injuries, improving security, increasing efficiency, and providing versatility, these systems prove to be a valuable asset in today's fast-paced and competitive business environment. Embracing this technology is not only a smart investment but also a proactive step towards creating a safer and more productive workplace for all.

- Future Trends in Warehousing Automation

In recent years, the automation of warehousing processes has seen significant advancements, with the introduction of robotic palletizing systems leading the charge. These cutting-edge systems have revolutionized the way goods are stored, sorted, and transported within warehouses, offering a myriad of benefits for companies looking to streamline their operations and increase efficiency.

One of the key advantages of a robotic palletizing system is the ability to dramatically improve speed and accuracy in the loading and unloading of goods. By utilizing advanced technology such as artificial intelligence and machine learning, these systems are able to quickly and efficiently stack and arrange products on pallets with precision, reducing the risk of errors and minimizing damage during transport. This not only saves time and labor costs but also improves overall productivity within the warehouse.

Furthermore, robotic palletizing systems can also enhance safety in the workplace by reducing the need for manual labor in hazardous or strenuous tasks. By taking on the heavy lifting and repetitive motions involved in palletizing, these systems help reduce the risk of injury to workers and create a safer working environment overall. This is especially important in industries where employees are often required to handle heavy or bulky items, such as in the manufacturing or logistics sectors.

In addition to improved efficiency and safety, robotic palletizing systems also offer increased flexibility and scalability for businesses looking to adapt to changing market demands. These systems can be easily programmed and reconfigured to handle a wide range of products, from small parcels to large and irregularly shaped items, making them ideal for companies with diverse product lines or seasonal fluctuations in demand. This adaptability allows businesses to stay agile and responsive to market trends, without the need for costly manual labor or retooling of equipment.

Looking ahead, it is clear that the future of warehousing automation lies in the continued development and integration of robotic palletizing systems. With advancements in technology such as robotics, artificial intelligence, and machine learning, these systems are set to become even more sophisticated and efficient in the years to come. This will not only benefit businesses by further improving productivity and reducing costs but also create new opportunities for innovation and growth within the warehousing industry.

In conclusion, the adoption of robotic palletizing systems represents a significant step forward in the evolution of warehouse automation, offering a wide range of benefits for businesses looking to optimize their operations and stay competitive in a rapidly changing market. By harnessing the power of technology and embracing the future trends in warehousing automation, companies can revolutionize their warehousing processes and pave the way for continued success in the years to come.

Conclusion

In conclusion, the implementation of a robotic palletizing system in warehouses can truly revolutionize the way goods are stored and shipped. From increasing efficiency and accuracy to reducing labor costs and improving workplace safety, the benefits of this advanced technology are undeniable. By embracing automation, companies can streamline their operations, boost productivity, and stay competitive in today’s fast-paced market. As technology continues to advance, the potential for further innovation in warehousing is limitless. It is clear that embracing robotic palletizing systems is a smart investment for any warehouse looking to optimize their processes and stay ahead of the curve.

Contact: Heidi

Tel: +86 183 2103 6277

E-mail: Heidi@cian-sung.com

WhatsApp:+86 183 2103 6277

Add:

【International Marketing Department】

11A Yindong BLG. No.58 Xinjinqiao RD. Pudong Shanghai, China

【Suzhou Factory】

No.111, Nanyuan Road, South District, Zhangjiagang Economic and Technological Development Zone, Jiangsu Province, China

【Xuzhou Factory】

No. 19 Wujiang Road, Taishang Industrial Zone, Yitang Town, Pizhou City, Jiangsu Province, China