The Future Of Logistics: Exploring The Benefits Of Automated Warehouse Systems

Welcome to the future of logistics! In this article, we will delve into the exciting world of automated warehouse systems and the myriad benefits they offer. From increased efficiency and accuracy to cost savings and improved customer satisfaction, the potential of automated logistics systems is truly revolutionary. Join us as we explore how these cutting-edge technologies are shaping the future of warehousing and distribution.

- Understanding the Evolution of Warehouse Automation

The evolution of warehouse automation has revolutionized the logistics industry, transforming the way goods are stored, picked, and shipped. With the rise of e-commerce and the increasing demand for faster delivery times, automated warehouse systems have become essential for businesses looking to streamline their operations and stay competitive in today's market.

One of the key benefits of automated warehouse systems is the increased efficiency they provide. By utilizing advanced technologies such as robotics, automated guided vehicles (AGVs), and conveyor systems, companies can drastically reduce the time it takes to fulfill orders and process shipments. This not only improves customer satisfaction but also allows businesses to handle larger volumes of orders without compromising on quality.

In addition to efficiency, automated warehouse systems also offer improved accuracy and reliability. With the use of barcode scanners, RFID technology, and inventory management software, companies can track their inventory in real-time, minimizing the risk of human error and ensuring that the right products are always in the right place at the right time. This level of precision is crucial for reducing costly mistakes and optimizing supply chain operations.

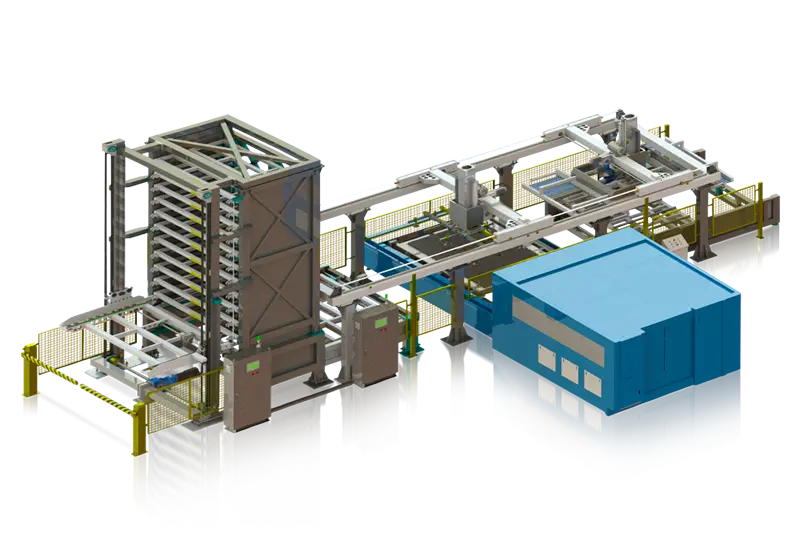

Furthermore, automated warehouse systems allow companies to maximize their warehouse space and layout. By utilizing vertical shelving systems, automated storage and retrieval systems (AS/RS), and automated sorting systems, businesses can make better use of their warehouse footprint and store more products in a smaller area. This not only saves on operational costs but also improves overall organization and inventory control.

Another key advantage of automated warehouse systems is their scalability. As businesses grow and expand, they can easily incorporate additional automation technologies to meet their changing needs. Whether it's adding more robots to handle increased order volumes or upgrading to a more advanced warehouse management system, companies can adapt their operations to stay ahead of the curve and meet the demands of a rapidly evolving market.

Overall, the evolution of warehouse automation has paved the way for a more efficient, accurate, and reliable logistics industry. By embracing automated warehouse systems, businesses can optimize their operations, reduce costs, and improve customer satisfaction. As technology continues to advance, the possibilities for automation in the warehouse are endless, and companies that invest in these technologies will undoubtedly reap the benefits in the long run.

- Advantages of Implementing Automated Systems in Logistics

In the ever-evolving world of logistics, the implementation of automated warehouse systems is becoming increasingly vital. These systems offer a wide range of advantages that can revolutionize the way businesses handle their supply chain operations. From increased efficiency to improved accuracy, automated warehouse systems are shaping the future of logistics in a profound way.

One of the key advantages of implementing automated warehouse systems is the significant increase in efficiency that they offer. By automating tasks such as picking and packing, these systems can dramatically reduce the time it takes to process and fulfill orders. This not only allows businesses to operate more quickly, but also enables them to handle a higher volume of orders with greater ease. As a result, businesses can streamline their operations and ultimately increase their profitability.

In addition to efficiency, automated warehouse systems also bring a level of accuracy that is unmatched by traditional manual processes. By utilizing advanced technology such as barcode scanning and RFID tracking, these systems are able to ensure that every item is accurately recorded and placed in the correct location. This not only reduces the risk of errors, but also helps to minimize the likelihood of stockouts and overstock situations. As a result, businesses can maintain better control over their inventory and provide a higher level of service to their customers.

Another key advantage of automated warehouse systems is the improved safety that they offer. By automating tasks that are traditionally done manually, these systems can help to reduce the risk of accidents and injuries in the workplace. For example, automated picking systems can minimize the need for workers to climb ladders or lift heavy items, reducing the likelihood of strain and injury. This not only creates a safer work environment for employees, but also helps to minimize the risk of costly worker compensation claims.

Furthermore, automated warehouse systems can also provide businesses with a more scalable solution for their operations. As businesses grow and expand, they can easily scale their automated systems to meet their changing needs. Whether they need to increase their order processing capacity or expand their warehouse footprint, automated systems offer a level of flexibility that is essential in today's fast-paced business environment. This allows businesses to adapt to changing market conditions and remain competitive in the industry.

In conclusion, the advantages of implementing automated warehouse systems in logistics are clear. From increased efficiency and accuracy to improved safety and scalability, these systems offer a wide range of benefits that can help businesses to optimize their supply chain operations. As technology continues to advance, automated warehouse systems will undoubtedly play a key role in shaping the future of logistics. Businesses that embrace these systems now will be well-positioned to thrive in the years to come.

- Impact of Automated Warehouse Systems on Operational Efficiency

In today's fast-paced and competitive business environment, companies are constantly seeking ways to improve their operational efficiency. One of the key trends shaping the future of logistics is the adoption of automated warehouse systems. These systems leverage cutting-edge technology to streamline warehouse operations, improve inventory management, and ultimately enhance overall efficiency.

Automated warehouse systems are revolutionizing the way businesses handle their logistics operations. By utilizing technologies such as robotics, artificial intelligence, and automation, companies can significantly reduce the time and resources required to manage their warehouses. These systems have the potential to transform the entire supply chain, from order fulfillment to inventory management, resulting in a more streamlined and efficient process.

One of the most significant impacts of automated warehouse systems is the reduction in labor costs. By automating tasks that were traditionally performed by human workers, companies can save time and resources while increasing productivity. With robots and automated systems handling tasks such as picking, packing, and shipping, companies can significantly reduce the need for manual labor, ultimately leading to cost savings and improved efficiency.

Another key benefit of automated warehouse systems is the improved accuracy and reliability of operations. By utilizing technologies such as barcode scanning, RFID tracking, and automated inventory management systems, companies can ensure that their products are always in the right place at the right time. This not only reduces the risk of errors and mistakes but also improves overall customer satisfaction by ensuring timely and accurate order fulfillment.

In addition to improving operational efficiency, automated warehouse systems also offer a number of other benefits. For example, these systems can help companies maximize their storage space, optimize inventory levels, and reduce the risk of stockouts or overstock situations. By utilizing real-time data and analytics, companies can gain valuable insights into their warehouse operations, allowing them to make informed decisions and improve overall performance.

Overall, the impact of automated warehouse systems on operational efficiency is clear. By leveraging cutting-edge technology and automation, companies can streamline their warehouse operations, reduce costs, and improve overall efficiency. As the future of logistics continues to evolve, it is clear that automated warehouse systems will play a key role in shaping the industry and driving competitive advantage for businesses around the world.

- Addressing Challenges and Concerns in Adopting Automation in Logistics

The Future of Logistics: Addressing Challenges and Concerns in Adopting Automation in Logistics

As the world of logistics continues to evolve, the adoption of automated warehouse systems is becoming increasingly prevalent. These innovative systems have the potential to revolutionize the way that goods are stored, picked, and shipped, leading to increased efficiency and cost savings for businesses. However, despite the numerous benefits that automated warehouse systems offer, there are also a number of challenges and concerns that must be addressed in order to fully realize their potential.

One of the main challenges in adopting automated warehouse systems is the initial cost of implementation. These systems require a significant upfront investment in terms of both capital and time, which can be a barrier for many businesses, especially smaller ones. Additionally, businesses may also need to invest in training for their employees in order to effectively operate and maintain the new automated systems.

Another concern that businesses may have when considering automation in their warehouses is the potential impact on their workforce. There is a fear that implementing automated systems could lead to job losses, as machines take over tasks that were previously done by humans. However, it is important to note that while some jobs may be eliminated, others may be created as a result of the increased efficiency and productivity that automation can bring.

Another challenge that businesses may face when adopting automated warehouse systems is the potential for technical issues and downtime. Like any technology, automated systems can experience glitches and malfunctions that can disrupt operations and lead to costly downtime. Additionally, businesses may also need to consider the ongoing maintenance and upgrades that are required to keep automated systems running smoothly.

Despite these challenges and concerns, the benefits of adopting automated warehouse systems are undeniable. These systems have the potential to significantly increase efficiency, accuracy, and productivity in warehouses, leading to cost savings and improved customer satisfaction. By streamlining processes such as inventory management, order picking, and shipping, businesses can reduce errors and delays, resulting in faster delivery times and improved overall performance.

In conclusion, while there are certainly challenges and concerns that must be addressed in adopting automation in logistics, the potential benefits of automated warehouse systems are too great to ignore. By carefully considering and planning for the initial costs, workforce implications, and technical challenges that may arise, businesses can successfully implement automated systems and reap the rewards of increased efficiency and productivity. The future of logistics is bright, and automated warehouse systems are sure to play a key role in shaping the industry for years to come.

- Embracing the Future: Maximizing the Potential of Automated Warehouse Systems

The future of logistics is rapidly evolving, and one of the key drivers of this transformation is the adoption of automated warehouse systems. These systems have the potential to revolutionize the way we think about warehouse operations, offering a host of benefits that can help businesses maximize efficiency, reduce costs, and improve overall performance.

One of the key advantages of automated warehouse systems is their ability to increase productivity by streamlining processes and reducing the need for human intervention. By utilizing technologies such as robotics, automated guided vehicles (AGVs), and automated sorting systems, warehouses can operate with greater speed and accuracy, leading to faster order fulfillment and reduced lead times. This not only improves customer satisfaction but also allows businesses to handle larger volumes of orders with greater ease.

In addition to boosting productivity, automated warehouse systems can also help businesses save money by reducing labor costs and minimizing errors. By automating repetitive tasks such as picking, packing, and sorting, businesses can eliminate the need for manual labor, thus reducing the risk of human error and increasing overall accuracy. This can result in lower operational costs and improved inventory management, leading to higher profits and greater scalability.

Furthermore, automated warehouse systems offer improved safety and security measures, ensuring that goods are handled with care and stored securely. By using advanced technologies such as sensors, cameras, and access control systems, warehouses can monitor and track inventory in real-time, reducing the risk of theft, damage, or loss. This not only helps businesses protect their assets but also provides peace of mind for both employees and customers.

Another key advantage of automated warehouse systems is their ability to adapt and grow with changing demands. By using sophisticated software and analytics tools, warehouses can optimize their operations in real-time, adjusting to fluctuations in demand, inventory levels, and other variables. This flexibility allows businesses to scale their operations up or down as needed, ensuring that they can meet the needs of their customers while remaining agile and responsive in a competitive market.

In conclusion, automated warehouse systems have the potential to transform the future of logistics by maximizing efficiency, reducing costs, and improving overall performance. By embracing these technologies and harnessing their full potential, businesses can position themselves for success in an increasingly competitive and demanding market. Automated warehouse systems are not just a trend or a passing fad – they are the future of logistics, and those businesses that embrace them will undoubtedly reap the rewards of their potential.

Conclusion

In conclusion, the future of logistics is incredibly bright with the implementation of automated warehouse systems. The benefits are clear, from increased efficiency and accuracy to cost savings and improved safety. As technology continues to advance and businesses strive to stay ahead of the competition, it is clear that automated warehouse systems will play a crucial role in the evolution of logistics. By embracing these innovations, companies stand to revolutionize their operations and create a more streamlined and successful supply chain. The time to invest in automated warehouse systems is now, and the possibilities are truly endless.

Contact: Heidi

Tel: +86 183 2103 6277

E-mail: Heidi@cian-sung.com

WhatsApp:+86 183 2103 6277

Add:

【International Marketing Department】

11A Yindong BLG. No.58 Xinjinqiao RD. Pudong Shanghai, China

【Suzhou Factory】

No.111, Nanyuan Road, South District, Zhangjiagang Economic and Technological Development Zone, Jiangsu Province, China

【Xuzhou Factory】

No. 19 Wujiang Road, Taishang Industrial Zone, Yitang Town, Pizhou City, Jiangsu Province, China