The Future Of Distribution: Navigating The World Of Automated Warehouses

In a rapidly evolving world where technology reigns supreme, automated warehouses are paving the way for the future of distribution. From robotics to artificial intelligence, these cutting-edge facilities are revolutionizing the way products are stored, picked, and shipped. Join us as we explore the exciting world of automated warehouses and discover how they are reshaping the landscape of distribution.

- The Rise of Automated Warehouses in Distribution

In today's fast-paced world, the distribution industry is constantly evolving to keep up with the increasing demands of consumers. One of the major trends shaping the future of distribution is the rise of automated warehouses. These high-tech facilities are revolutionizing the way goods are stored, picked, and shipped, allowing for greater efficiency, accuracy, and speed in the supply chain.

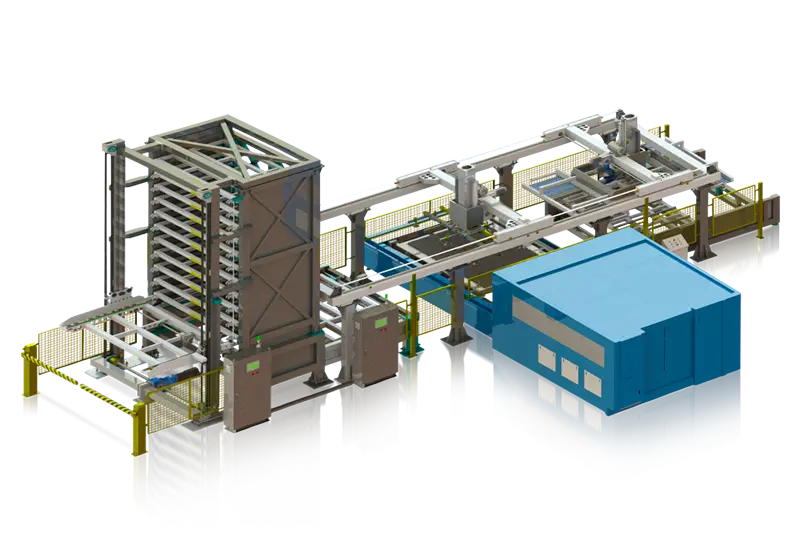

Automated warehouses utilize cutting-edge technologies such as robotics, artificial intelligence, and machine learning to streamline the distribution process. These technologies work together to perform tasks that were once done manually, such as inventory management, order fulfillment, and even delivery. By automating these processes, companies can reduce human error, lower operating costs, and improve overall productivity.

One of the key benefits of automated warehouses is their ability to operate 24/7 without the need for breaks or rest periods. This constant uptime ensures that orders can be processed and shipped quickly, meeting the demands of today's consumers for fast and reliable delivery. Additionally, the use of robotics in automated warehouses allows for more efficient use of space, as robots can navigate narrow aisles and stack goods higher than human workers.

Another advantage of automated warehouses is their ability to adapt to changing market conditions. By using data analytics and machine learning algorithms, these facilities can adjust their processes in real-time based on factors such as demand fluctuations, inventory levels, and shipping costs. This agility allows companies to stay competitive in a dynamic market environment and meet customer expectations for speedy delivery and accurate order fulfillment.

While the benefits of automated warehouses are clear, there are also challenges that come with implementing this technology. The initial cost of setting up an automated warehouse can be high, requiring significant investment in equipment, software, and training. Additionally, the complexity of these systems can pose challenges in terms of maintenance and troubleshooting, requiring skilled technicians to keep operations running smoothly.

Despite these challenges, the future of distribution is clearly moving towards automated warehouses. Companies that invest in this technology are likely to see significant benefits in terms of operational efficiency, cost savings, and customer satisfaction. As the technology continues to evolve and become more advanced, we can expect to see even greater innovations in the world of automated warehouses, shaping the way goods are stored and shipped for years to come.

- Key Technologies Driving Automation in Warehousing

In today's rapidly evolving world of distribution, the emergence of automated warehouses has revolutionized the way goods are stored, picked, packed, and shipped. With advancements in key technologies driving automation, warehouses are becoming more efficient, accurate, and cost-effective than ever before. This article will explore the key technologies driving automation in warehousing and how they are shaping the future of distribution.

One of the key technologies driving automation in warehouses is robotics. With the advancements in robotics technology, warehouses are now able to automate tasks that were once done manually, such as picking and packing. Autonomous mobile robots (AMRs) are being used to navigate warehouse aisles, pick items from shelves, and transport them to packing stations. These robots are equipped with sensors and cameras that allow them to move safely and efficiently throughout the warehouse, increasing productivity and reducing errors.

Another key technology driving automation in warehouses is artificial intelligence (AI). AI-powered systems are being used to optimize warehouse operations by analyzing data, predicting trends, and making real-time decisions. Machine learning algorithms are being used to improve inventory management, optimize routing, and reduce cycle times. AI-powered systems are also being used to automate repetitive tasks, such as sorting and labeling, freeing up human workers to focus on more complex, value-added tasks.

In addition to robotics and AI, the Internet of Things (IoT) is also playing a key role in driving automation in warehouses. IoT devices, such as sensors and RFID tags, are being used to track the location and status of goods in real-time. These devices are allowing warehouses to monitor inventory levels, track shipments, and prevent stockouts. IoT devices are also being used to optimize energy usage, monitor equipment health, and improve worker safety.

Furthermore, automation technologies such as warehouse management systems (WMS) and automated guided vehicles (AGVs) are also contributing to the efficiency and accuracy of warehouse operations. WMS software is being used to track inventory, manage orders, and optimize warehouse layout. AGVs are being used to transport goods within the warehouse, reducing the need for manual labor and increasing speed and accuracy.

As automated warehouses continue to evolve and expand, businesses are reaping the benefits of increased efficiency, accuracy, and cost savings. By leveraging key technologies such as robotics, AI, IoT, WMS, and AGVs, warehouses are able to handle increasing order volumes, reduce fulfillment times, and improve customer satisfaction. The future of distribution is indeed bright, as we navigate the world of automated warehouses and embrace the possibilities that automation has to offer.

- Advantages and Challenges of Implementing Automated Systems

Automated warehouses are quickly becoming the future of distribution, revolutionizing the way products are stored, picked, and shipped. The implementation of automated systems in warehouses offers a multitude of advantages, but also presents several challenges that must be carefully navigated.

One of the key advantages of automated warehouses is increased efficiency. By utilizing advanced technologies such as robotics and artificial intelligence, warehouses are able to operate 24/7 with minimal human intervention. This allows for faster order processing and reduced lead times, ultimately improving customer satisfaction. Furthermore, automated systems are able to optimize the use of space within a warehouse, maximizing storage capacity and reducing the need for additional facilities.

In addition to increased efficiency, automated warehouses also offer improved accuracy. Human error is minimized with automated systems, leading to fewer mistakes in order processing and inventory management. This not only reduces the risk of costly errors but also enhances overall inventory control, leading to better stock management and forecasting capabilities.

Another advantage of implementing automated systems in warehouses is the ability to scale operations quickly and easily. As demand fluctuates, automated systems can be easily adjusted to accommodate changing order volumes. This flexibility allows warehouses to adapt to market conditions and customer preferences more effectively, ensuring that products are delivered in a timely manner.

However, the implementation of automated systems in warehouses also presents several challenges. One of the main challenges is the high initial cost of installing and maintaining these systems. The technology required for automation can be expensive, requiring significant investment from warehouse operators. Additionally, training employees to operate and maintain automated systems can also be costly and time-consuming.

Another challenge of implementing automated systems in warehouses is the potential for job displacement. As more tasks become automated, there is a risk that traditional warehouse jobs may become obsolete. This can lead to concerns about job security and the future of the workforce in the distribution industry.

Despite these challenges, the benefits of automated warehouses far outweigh the drawbacks. By embracing automation, warehouse operators can streamline their operations, improve efficiency, and stay competitive in an increasingly fast-paced market. The future of distribution is automated, and those who are able to effectively implement and navigate the world of automated warehouses will undoubtedly reap the rewards.

- The Impact of Automation on Supply Chain Management

In today’s fast-paced world, the future of distribution is rapidly evolving with the rise of automated warehouses. These cutting-edge facilities are revolutionizing the way supply chain management is conducted, offering a plethora of benefits and challenges for businesses around the globe.

Automated warehouses utilize advanced technologies such as robotics, AI, and IoT to streamline operations and increase efficiency. These state-of-the-art systems are capable of performing various tasks, including inventory management, order fulfillment, and shipping, with minimal human intervention. By harnessing the power of automation, companies can significantly reduce labor costs and improve overall productivity.

One of the key advantages of automated warehouses is their ability to enhance accuracy and speed in the logistics process. With automated systems in place, the likelihood of errors and delays is greatly reduced, leading to faster order processing and increased customer satisfaction. Additionally, these facilities are equipped with sophisticated tracking and monitoring tools, allowing businesses to have real-time visibility into their inventory levels and shipping statuses.

Furthermore, automated warehouses are designed to optimize space utilization and inventory management. Through the use of intelligent algorithms and data analytics, these facilities can determine the most efficient layout for storing products and fulfill orders in the most cost-effective manner. This not only helps businesses save on storage costs but also enables them to respond quickly to changing market demands.

Despite the numerous benefits of automated warehouses, there are also challenges that businesses must overcome. Implementing automation technologies can be a costly investment, requiring substantial capital and operational expenses. Moreover, the integration of these systems into existing supply chain processes can be complex and time-consuming, requiring careful planning and coordination.

Additionally, concerns have been raised regarding the potential impact of automation on the workforce. As more tasks are automated, the need for human labor may diminish, leading to job displacement and re-skilling requirements. It is crucial for businesses to address these challenges proactively and ensure a smooth transition to automated warehouse operations while maintaining a balance between human and machine interaction.

In conclusion, the future of distribution is undeniably intertwined with the growth of automated warehouses. By embracing these innovative technologies, businesses can enhance their operational efficiency, reduce costs, and improve customer satisfaction. However, it is essential for companies to carefully consider the implications of automation on their workforce and develop strategies to mitigate any potential negative impacts. Only by navigating the world of automated warehouses with a thoughtful and strategic approach can businesses truly unlock their full potential in the evolving landscape of supply chain management.

- Strategies for Successfully Navigating Automated Warehouses in the Future

In the fast-paced world of distribution and logistics, automated warehouses are becoming increasingly prevalent. With advancements in technology like robotics, artificial intelligence, and the Internet of Things (IoT), these warehouses are revolutionizing the way goods are stored, picked, packed, and shipped. However, navigating this brave new world of automation can be daunting for those unfamiliar with the intricacies of these high-tech facilities.

One of the key strategies for successfully navigating automated warehouses in the future is to understand the technology that powers them. From automated guided vehicles (AGVs) that transport goods around the warehouse to robotic arms that pick and pack orders, these technologies are changing the face of distribution. By familiarizing themselves with these technologies, warehouse managers can better understand how to optimize their operations and maximize efficiency.

Another crucial aspect of successfully navigating automated warehouses is ensuring proper training for warehouse staff. As technology continues to advance, the role of human workers in warehouses is evolving. Workers must be trained to operate and maintain the automated systems in the facility, as well as to work alongside robots and other technologies. By investing in training programs and upskilling their workforce, warehouse managers can ensure that their staff are equipped to handle the challenges of an increasingly automated world.

Furthermore, connectivity is key to navigating automated warehouses in the future. With the rise of IoT technology, warehouses are becoming increasingly interconnected, with sensors and devices communicating with each other in real time. By leveraging this connectivity, warehouse managers can gain greater visibility into their operations, track inventory more accurately, and optimize their processes for greater efficiency. Additionally, cloud-based software systems can help warehouse managers monitor and manage their operations remotely, giving them greater flexibility and control over their facilities.

In addition to technology and training, collaboration is essential for successfully navigating automated warehouses in the future. As the industry evolves, warehouse managers must work closely with technology providers, suppliers, and other partners to stay ahead of the curve. By fostering strong partnerships and sharing knowledge and best practices, warehouse managers can position themselves for success in the increasingly automated world of distribution.

In conclusion, the future of distribution lies in automated warehouses. By understanding the technology that powers these facilities, investing in training for staff, leveraging connectivity, and fostering collaboration, warehouse managers can successfully navigate the challenges and opportunities that come with automation. As the industry continues to evolve, those who embrace automation and adapt to the changing landscape will thrive in the fast-paced world of distribution.

Conclusion

In conclusion, the future of distribution lies in the realm of automated warehouses. As technology continues to advance, businesses must adapt and embrace automation in order to stay competitive in the rapidly evolving market. By efficiently utilizing automated systems, companies can streamline their operations, reduce costs, and improve overall efficiency. It is clear that automated warehouses are revolutionizing the distribution industry, and those who embrace this innovative technology will undoubtedly thrive in the future. So, as we navigate the world of automated warehouses, let’s remember to embrace the future and leverage technology to drive success and growth in our businesses.

Contact: Heidi

Tel: +86 183 2103 6277

E-mail: Heidi@cian-sung.com

WhatsApp:+86 183 2103 6277

Add:

【International Marketing Department】

11A Yindong BLG. No.58 Xinjinqiao RD. Pudong Shanghai, China

【Suzhou Factory】

No.111, Nanyuan Road, South District, Zhangjiagang Economic and Technological Development Zone, Jiangsu Province, China

【Xuzhou Factory】

No. 19 Wujiang Road, Taishang Industrial Zone, Yitang Town, Pizhou City, Jiangsu Province, China