Warehouse Automation Companies with Good Price for Industry

Product details of the warehouse automation companies

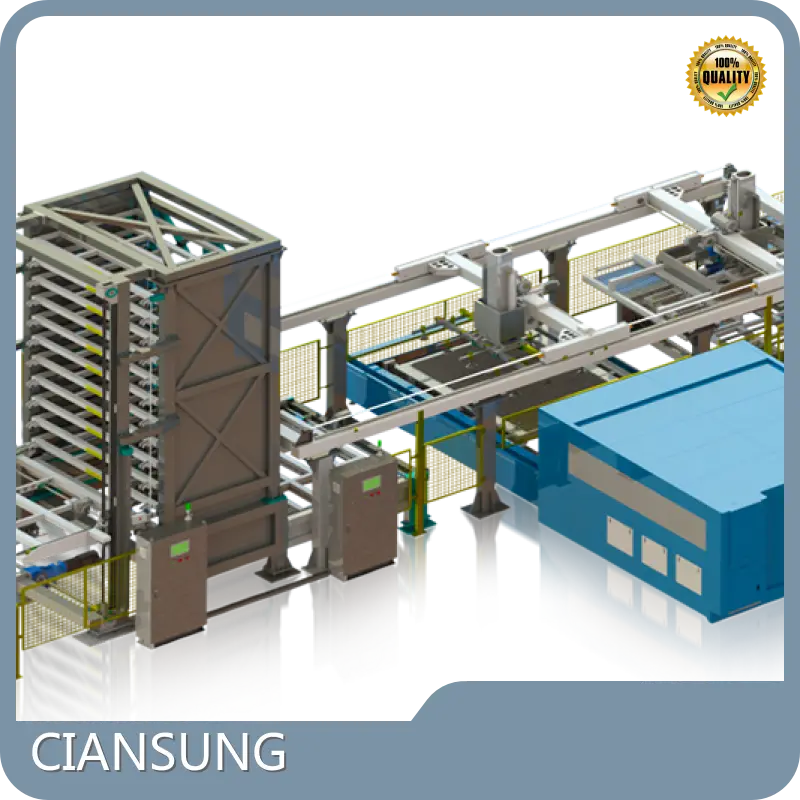

Product Overview

Our design team has strong innovation capacity, making sure our CIANSUNG warehouse automation companies has a variety of innovative, aesthetically-pleasing, and functional designs. No complaint about the production quality and performance has been received. CIANSUNG's warehouse automation companies is widely applicable in the industry. The product sells well throughout the world and is well received by users.

Product Introduction

In order to strengthen your understanding of warehouse automation companies, CIANSUNG will show you the specific details of warehouse automation companies in the following section.

Sheet metal standing warehouse can realize automatic three-dimensional sheet metal into the warehouse, automatic access, optional two rows of two-way magazine, the use of elevated warehouse, make full use of the warehouse floor and space, improve space utilization. Improve labor productivity, reduce operator labor intensity, reduce freight handling and information processing errors, save working capital and improve inventory management, warehouse information electronic signage real-time information display, and a variety of ERP real-time data exchange.

The sheet metal warehouse system is a system that automatically stores and retrieves goods without manual direct processing. There are three types of sheet metal warehouse control modes: centralized control, decentralized control and decentralized control. Distributed control is the main direction of international development at present. Large-scale sheet metal warehouses usually use computer distributed control systems. The control system consists of management layer, intermediate control layer and direct control layer.Large sheet metal three-dimensional warehouse usually adopts computerized centralized control system. The control system consists of management layer, intermediate control layer and direct control layer.

The professional integrator of sheet metal standing warehouse system has to provide complete logistics network planning, logistics system design and integration, warehousing equipment design and manufacturing, as well as seamless connection with ERP system.Sheet metal warehouses have a wide range of applications, such as logistics, industrial production, pharmaceutical production, electronic manufacturing, automobile manufacturing, etc.

Product Parameter

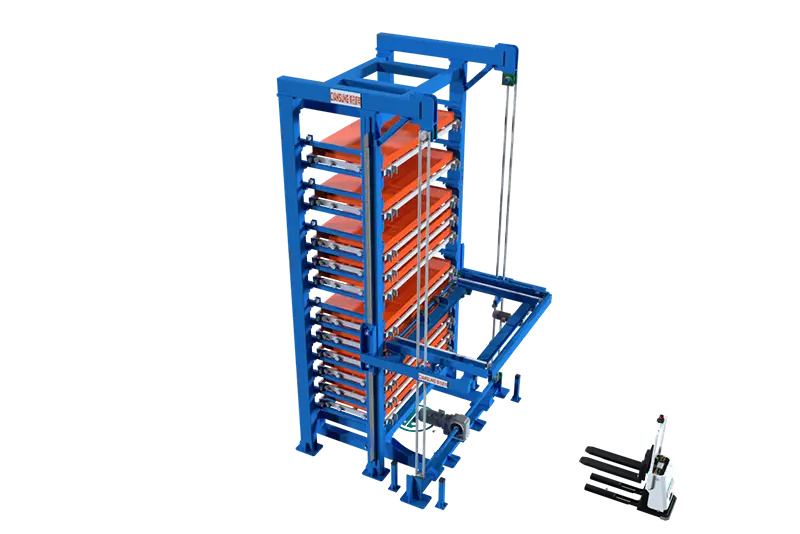

The CIANSUNG Stereo Warehouse consists of three parts: a dimensional warehouse, a lift truck, and a storage pallet. In addition, it can be used with robotic forklift and ERP systems to realize unmanned factories. The parameters of each part are:

|

Dimensional Warehouse |

|

|

Number of layers |

6-15 |

|

Weight |

3-7T |

|

Height |

4-8m |

|

Layer spacing |

430mm |

|

ootprint size (length*width) |

4700*4400mm |

|

Lift Truck |

|

|

Maximum lifting weight |

5t |

|

Maximum lifting speed |

200mm/s |

|

Maximum push-pull tray speed |

200mm/s |

|

Storage Pallet |

|

|

Tray size |

3200*1650mm |

|

Adapt to the size of sheet metal material |

3000*1500mm |

|

Pallet weight |

170kg |

Product advantage

Sheet metal standing storage operation process

The main body of a sheet metal standing warehouse consists of shelves, alley stacking cranes, inlet (outlet) tables and automatic inlet (outlet) and operation control systems. A rack is a steel or reinforced concrete building or structure with a standard size cargo space inside. The aisle stacker crane travels through the aisles between the racks to complete the storage and retrieval work; it is controlled and managed by the WCS system.

● Inventory Process: The Sheet Metal LIBOR system responds to the request for inventory, pops up the inventory dialog box, and the user fills in the name and quantity of the goods to be inventoried;

● The system queries the order quantity. If the order quantity is greater than the inventory quantity of the goods, an alarm will be issued. Otherwise, the sheet metal warehouse system sends a warehouse operation task list to the warehouse computer, prints the warehouse document, and the warehouse computer controls the barcode system to scan the goods. After scanning, the warehouse computer will determine whether the scanned goods and the task are consistent. If they are consistent, storage sorting and transportation will be carried out. If they are inconsistent, an alarm signal will be issued.

● Packaging and boxing: Before small goods or parts enter the sheet metal warehouse, they are generally required to be packaged and boxed to meet storage requirements and make full use of storage space.

● Barcode Input: The barcode representing the goods in a sheet metal standing warehouse generally contains four types of information: pallet number, article number, lot number, and quantity. The barcode is read in by the scanner, interpreted by the decoder, and then transferred to the computer via the serial port interface.

● Outbound process: The process of goods out of the sheet metal warehouse is as follows: the system responds to the outbound request, a dialog box pops up, and the user fills in the name and quantity of the goods out of the warehouse.

Company Advantages

CIANSUNG owns high reputation in the warehouse automation companies market. The factory, with advanced production machines and testing instruments, has increased the overall technical level to ensure stable monthly output and product quality. We are working hard to become an innovative leader in this warehouse automation companies field. We will invest more capital and talent resources in cultivating our R&D team to continuously promote technological innovation.

For bulk purchase of the products, please contact us.

Contact: Heidi

Tel: +86 183 2103 6277

E-mail: Heidi@cian-sung.com

WhatsApp:+86 183 2103 6277

Add:

【International Marketing Department】

11A Yindong BLG. No.58 Xinjinqiao RD. Pudong Shanghai, China

【Suzhou Factory】

No.111, Nanyuan Road, South District, Zhangjiagang Economic and Technological Development Zone, Jiangsu Province, China

【Xuzhou Factory】

No. 19 Wujiang Road, Taishang Industrial Zone, Yitang Town, Pizhou City, Jiangsu Province, China