Robotic Automation Solutions for Manufacturing Eries

Product details of the robotic automation solutions

Product Overview

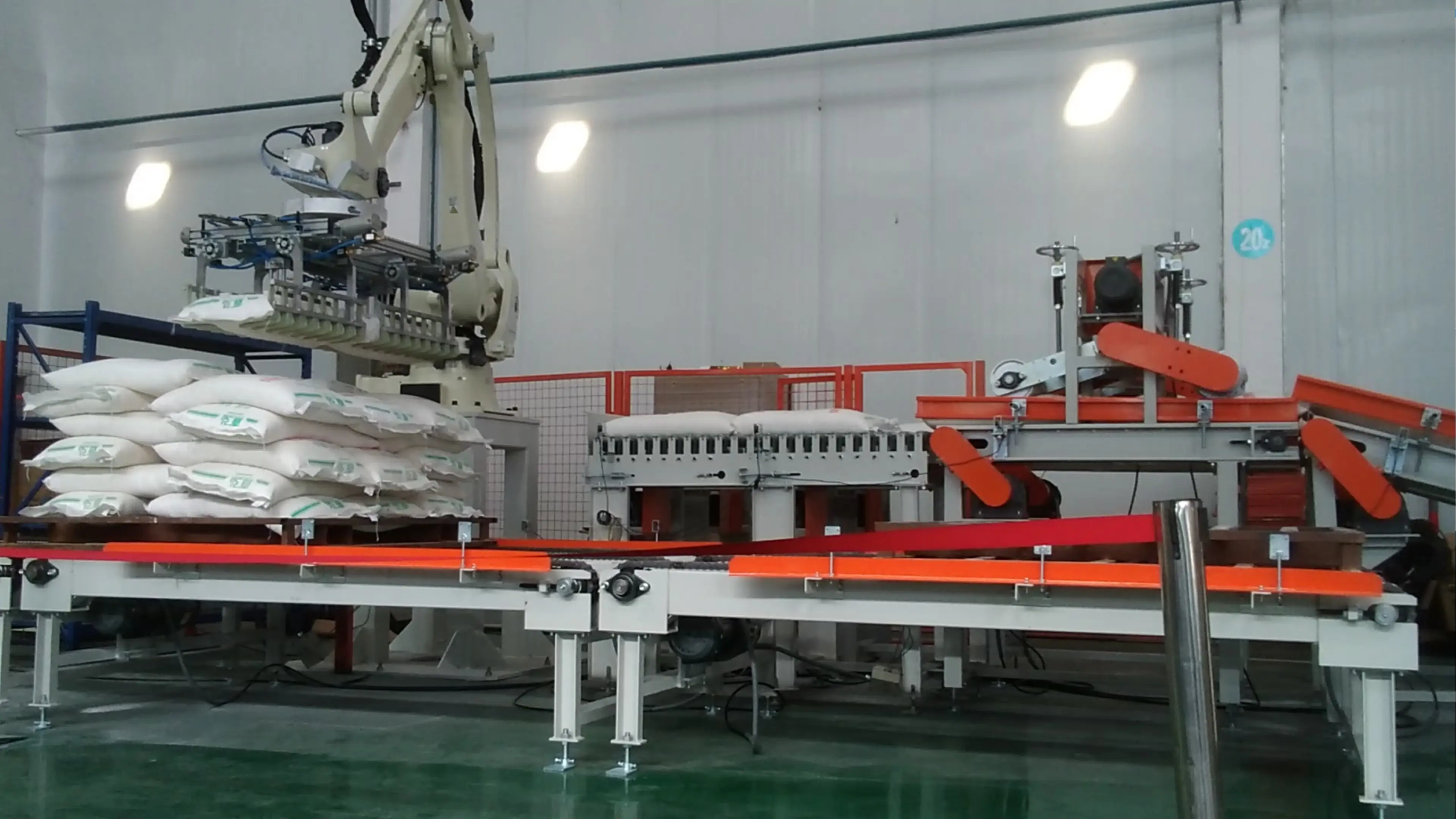

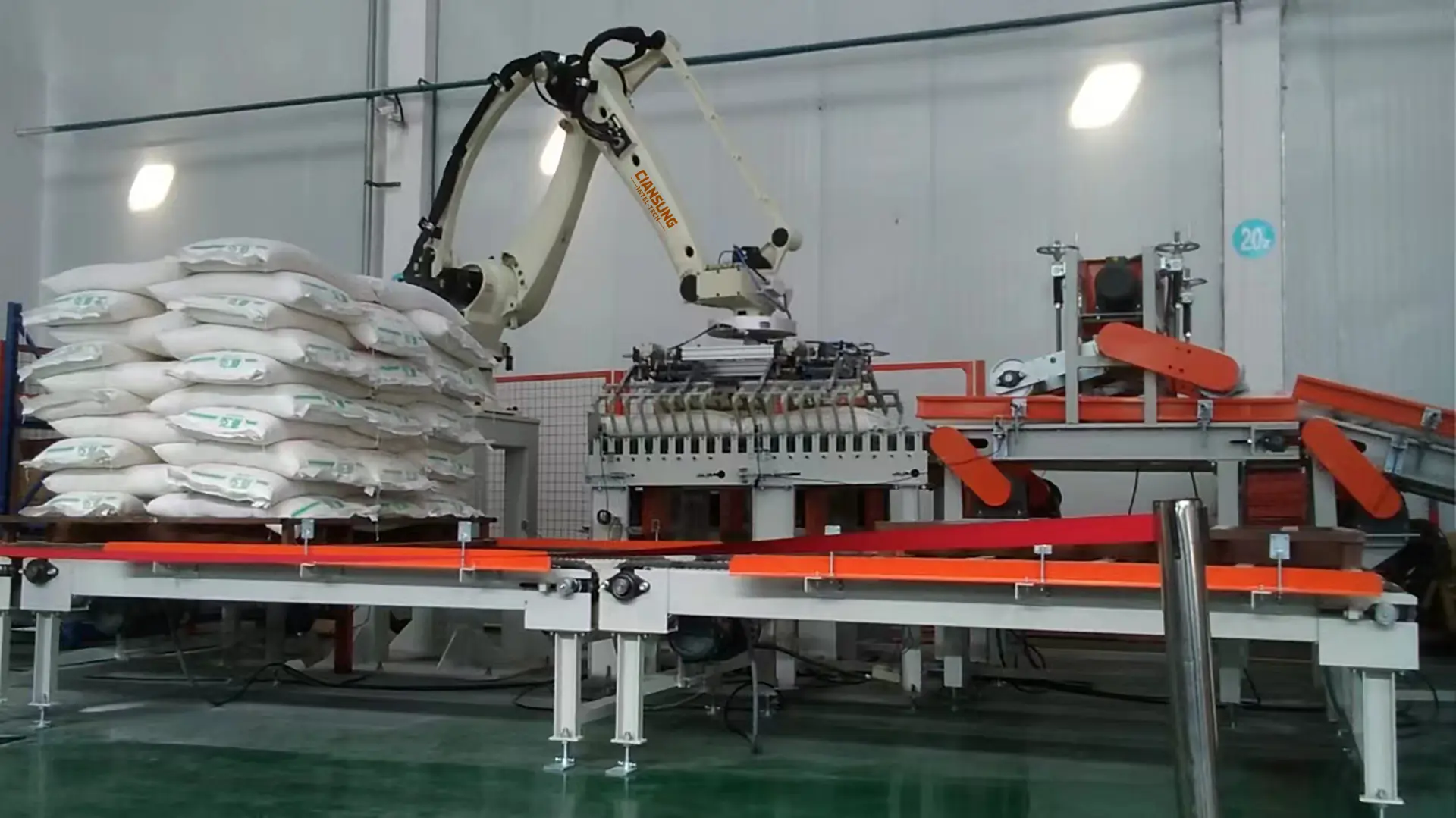

CIANSUNG robotic automation solutions is manufactured by the inclusion of modern machines and sophisticated techniques in the production process. The product performance has been greatly improved by our innovative R&D team. The robotic automation solutions of CIANSUNG can be used in many industries. The product has gained many loyal customers and will be further applied to the market with constant improvement.

Product Information

Compared with other similar products, our robotic automation solutions has more advantages, specifically in the following aspects.

CIANSUNG multifunctional industrial robotic palletizer increases efficiency and productivity, reduces labor costs, and ensures precise and accurate palletizing for various industries.

CIANSUNG has extensive experience in palletizing cartons, bags, barrels, glass bottles and frozen food. And we can provide overall solutions from loading and unloading, handling and stacking, to warehousing, making your production line more flexible and greatly improving product rates, which is exactly what is needed in today's commercial competition.

Product parameter

|

Robot model |

CS-MD130 |

CS-MD180 |

CS-MD210 |

|

|

Maximum range of action |

J1 |

±3.14rad*1 |

||

|

J2 |

+0.71~-1.65rad |

|||

|

J3 |

+0.30~-2.04rad |

|||

|

J4 |

±6.28rad |

|||

|

Maximum speed |

J1 |

2.27rad/s |

2.01rad/s |

1.83rad/s |

|

J2 |

2.01rad/s |

1.75rad/s |

1.75rad/s |

|

|

J3 |

2.01rad/s |

1.83rad/s |

1.75rad/s |

|

|

J4 |

6.98rad/s |

6.28rad/s |

5.24rad/s |

|

|

Maximum removable mass |

Wrist |

130kg |

180kg |

210kg |

|

Maximum allowable moment of inertia of the wrist |

J4 |

50kg・m2 |

69kg・m2 |

100kg・m2 |

|

*2 Position repetition accuracy |

±0.3mm |

±0.4mm |

||

|

Structure |

Joint type |

|||

|

Number of joints |

4 |

|||

|

Drive mode |

AC Servo mode |

|||

|

Air hose |

-101.3kPa~690kPa |

|||

|

Use air pressure |

2-φ12x8 )(To wrist) |

|||

|

Signal line for application |

20620 cores (to wrist) 6 cores (to the first arm) |

|||

|

Setting method |

Ground installation |

|||

|

Set conditions*3 |

0~45°C20~85 %RH0.5G Ambient temperature: 0~45°C Surrounding humidity: 20~85%RH (no condensation) Allowable vibration of the mounting surface: below 0.5G |

|||

|

Body quality |

1,150kg |

|||

Product advantage

● [rad] = 180/π[°],1[N・m] = 1/9.8[kgf・m]

● “JIS B 8432”。

● 1,000m. Use below 1,000 meters above sea level. When the allowable height is exceeded, the surrounding temperature is limited.

Company Information

After continuous independent innovation of robotic automation solutions, CIANSUNG has become a well-known top supplier in this industry. CIANSUNG possesses polished equipment, solid techniques and complete quality system. CIANSUNG endeavors to meet your particular service requirements. Check now!

Do not hesitate to contact us if you are interested in our

Contact: Heidi

Tel: +86 183 2103 6277

E-mail: Heidi@cian-sung.com

WhatsApp:+86 183 2103 6277

Add:

【International Marketing Department】

11A Yindong BLG. No.58 Xinjinqiao RD. Pudong Shanghai, China

【Suzhou Factory】

No.111, Nanyuan Road, South District, Zhangjiagang Economic and Technological Development Zone, Jiangsu Province, China

【Xuzhou Factory】

No. 19 Wujiang Road, Taishang Industrial Zone, Yitang Town, Pizhou City, Jiangsu Province, China