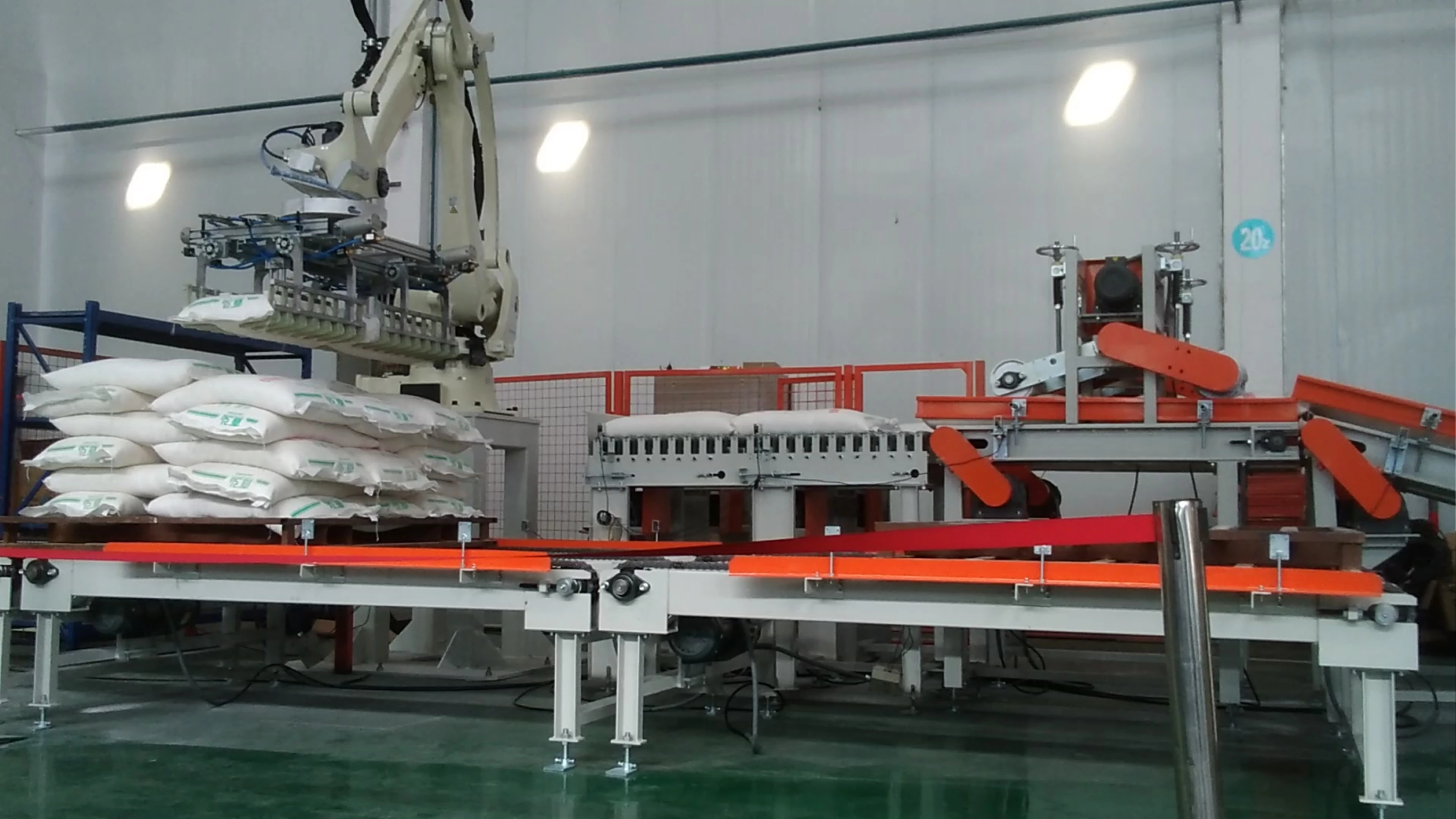

CIANSUNG Multifunctional Industrial Robotic Palletizer High-Speed

Palletizing, as the last step of the product on the assembly line before it is loaded on the truck for shipment, is a demanding process of stacking boxes, bags, boxes, bottles, cartons, etc. on pallets. At present, there are three major challenges faced by automatic palletizing operations in the industry: the flexibility of pallet mode, tooling flexibility and cycle time. CIANSUNG palletizing system provides corresponding solutions for each of the above palletizing challenges. Our professional palletizing robot designed for customers with high-speed, large-load and long-distance palletizing needs can quickly generate pallet patterns through various options and monitor the status of the palletizing system.

CIANSUNG multifunctional industrial robotic palletizer increases efficiency and productivity, reduces labor costs, and ensures precise and accurate palletizing for various industries.

CIANSUNG has extensive experience in palletizing cartons, bags, barrels, glass bottles and frozen food. And we can provide overall solutions from loading and unloading, handling and stacking, to warehousing, making your production line more flexible and greatly improving product rates, which is exactly what is needed in today's commercial competition.

Product parameter

|

Robot model |

CS-MD130 |

CS-MD180 |

CS-MD210 |

|

|

Maximum range of action |

J1 |

±3.14rad*1 |

||

|

J2 |

+0.71~-1.65rad |

|||

|

J3 |

+0.30~-2.04rad |

|||

|

J4 |

±6.28rad |

|||

|

Maximum speed |

J1 |

2.27rad/s |

2.01rad/s |

1.83rad/s |

|

J2 |

2.01rad/s |

1.75rad/s |

1.75rad/s |

|

|

J3 |

2.01rad/s |

1.83rad/s |

1.75rad/s |

|

|

J4 |

6.98rad/s |

6.28rad/s |

5.24rad/s |

|

|

Maximum removable mass |

Wrist |

130kg |

180kg |

210kg |

|

Maximum allowable moment of inertia of the wrist |

J4 |

50kg・m2 |

69kg・m2 |

100kg・m2 |

|

*2 |

±0.3mm |

±0.4mm |

||

|

Structure |

Joint type |

|||

|

Number of joints |

4 |

|||

|

Drive mode |

AC Servo mode |

|||

|

Air hose |

-101.3kPa~690kPa |

|||

|

Use air pressure |

2-φ12x8 )(To wrist) |

|||

|

Signal line for application |

20 |

|||

|

Setting method |

Ground installation |

|||

|

Set conditions*3 |

0~45°C |

|||

|

Body quality |

1,150kg |

|||

Product advantage

● [rad] = 180/π[°],1[N・m] = 1/9.8[kgf・m]

● “JIS B 8432”。

● 1,000m. Use below 1,000 meters above sea level. When the allowable height is exceeded, the surrounding temperature is limited.

Contact: Heidi

Tel: +86 183 2103 6277

E-mail: Heidi@cian-sung.com

WhatsApp:+86 183 2103 6277

Add:

【International Marketing Department】

11A Yindong BLG. No.58 Xinjinqiao RD. Pudong Shanghai, China

【Suzhou Factory】

No.111, Nanyuan Road, South District, Zhangjiagang Economic and Technological Development Zone, Jiangsu Province, China

【Xuzhou Factory】

No. 19 Wujiang Road, Taishang Industrial Zone, Yitang Town, Pizhou City, Jiangsu Province, China